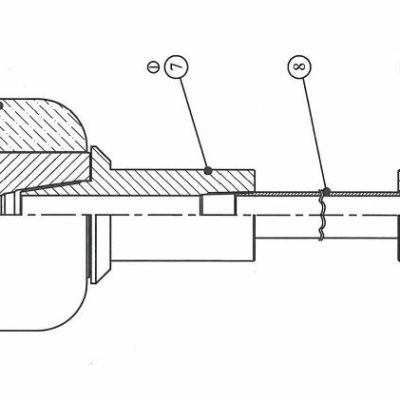

Our 4-7.0 CRTi’s manufactured by Volant are designed for casing drilling or running with top drive equipped rigs to enable makeup, breakout, reciprocate, rotate, fill/circulate, and cement casing and liner strings, reducing non-productive time and associated costs.

Our Internal Grip Casing Running Tools (CRTi) parameters include:

- Casing Size Range: 20” – 7” Casing

- Rated Load Capacity 420 ton

- Set Down Load Capacity 110 ton

- Typical Circulation Pressure Limit 5000 psi

- Maximum flow Rate 660 GPM

- Through Hole 1.5”

- Combined Load High Torque 50,000 ft/lbs @ 200 Ton. 30,000 ft/lbs @ 300 Ton

- Tool Overall Length 72”

TRADITIONAL CASING RUNNING METHODS VS CASING RUNNING TOOLS

- Traditional casing running methods are accompanied by:

- Power tongs

- Casing elevators/handling equipment

- Fill up/circulation tools

- Numerous people to operate and handle all equipment

- Logistic challenges for equipment and personnel

- Planned and unplanned NPT (Non Productive Time)

- Intensive maintenance and certification requirements

- Opportunities for numerous pieces of equipment to break down

- Our internal grip Casing Running Tools removes complex processes, requiring less equipment and manpower

- Simplifying operating procedures, offering improved safety and more productive time

HOW IS THE VOLANT CRT DIFFERENT THAN OTHER CRT’S USED IN OUR INDUSTRY?

- 100% Mechanical, controlled by the Driller via the Top Drive

- Threads onto the quill of any top drive

- NO external control panel, NO external HPU or connections

- Closely imitating the make and break steps used to run drill pipe-stab, right hand rotation to engage and left hand rotation to disengage, this mechanically activated tool puts control in the hands of the driller using Top Drive controls.

- Compact tool design allows for rig bails to be used

SAFETY

- Safety enhanced through elimination of extra drilling and service personnel from the rig floor.

- Removes the need for extra equipment on the rig floor.

- Mechanical interlock is failsafe and protects against accidental and unintentional release.

- Fewer resources are needed to transport equipment, which in turn reduces the carbon footprint and environmental impact.

EFFICIENCY

- Efficient design is small, lightweight, and robust with very few moving parts.

- Easy to transport and store with minimal requirements for maintenance and service.

- Fully mechanical operation with no external control panel or HPU, eliminating the need for hydraulic or pneumatic connections.

- Driller is in full control of the CRTi.

- Option to monitor and record torque with a wireless torque sub (Premium Connections)

- Simple to operate and significantly reduces rig-in and rig-out time.

- Existing bails, extensions and link tilts used for pipe handling on v-door rigs.

EFFECTIVENESS

- Reduces the risk of stuck pipe and improves runability by providing on-demand functions, including hoist, circulation, rotation, reciprocation, fill-up, and pushdown capabilities.

- No need to rig-in auxiliary equipment.

- Reduces scheduled and non-

scheduled non-productive time (NPT) during tubular running operations. - Allows you to fill pipe on the fly.